Too much argon will actually disturb your welding puddle

- Luis Alejandro

- Oct 4, 2022

- 2 min read

Updated: Apr 27, 2023

Did you know you don't actually have to set your argon pressure to max to accomplish a good TIG weld?

You read that right, yes you, the welder that likes to set the argon flow to max on a flowmeter when welding TIG or that one welder that installs a pressure gauge to get that extra pump out of the argon tank.

So, what is too much pressure anyway?

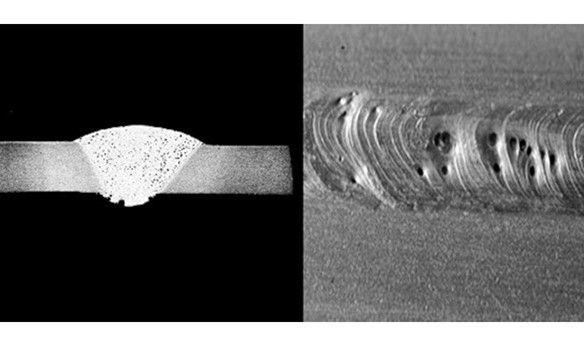

Turns out, setting your argon flow or pressure too high on the regulator will actually disturb your welding puddle because the gas will cause unnesessary vibrations on the weld puddle which may compromise quality. Alongside distubring the puddle, defects such as undercut while "capping" a pipe (from pushing the puddle out), and having your weld puddle bounce and catch the tip of your tungsten, you will also notice your argon bottle running out alot quicker which could have been easily prevented and would have saved you extra money.

The distance sets the flow

Setting the correct gas pressure can be determined using a couple of variables which are the length of argon hose from argon gas source to torch, size of the welding tig cup to be used for gas coverage, and the actual material that is being welded and it's metallurgic properties. While we could go into a deep tangent deciding the correct formulas, a useful rule of thumb is that if you're welding between 5 to 20 feet from the argon source, you can set your argon flow between 25 to 35 CFH, increasing the distance will require adjusting the flow.

Adjust accordingly

This is not a definitive guide to setting your argon flow, however, setting your argon to max settings because that is what you have been told by others does not mean that you will have the best results, and it may turn out you are just wasting money. Good things, even in excess, can be detrimental to your results.

What do you think?

Do you think it's necessary to keep a close eye on the argon flow? or should we just set it and forget it? I'm a strong believer that improving processes every day can help us become better welders and become more efficient as well!

About the author: Luis Alejandro is the owner and one of the instructors at Southern Arc Welding Services Ltd. Co.. He enjoys family, reading books on history, and writing to share his knowledge about the many situations welding can place us in.

Comments